Our Philosophy. 002 Locally Made

We are so proud to make our jewellery locally. We work with some amazing individuals and collectively treat our makers as part of our Alice Made This family. Here you can learn a bit more about each of them as we go deeper into our community and understand why they are so special to work with. Our Craftspeople, their skills, and their materials are the blood the runs through the veins of Alice Made This. We create relationships through a shared passion for materials, quality, detail, and finesse. I feel very grateful to know everyone we work with, and I always enjoy making these new relationships. We do not just work together. We know each other, respect each other, and we learn and share with each other. I wholeheartedly believe that this is what ‘good business’ is.

Meet the Experts!

Aerospace

This is our founding process and one that has become our signature. The precise, clean and graphic aesthetic is where Alice Made This began. Proportions of these pieces are driven by geometry in nature, and we delve into the world of engineering to realise this minimal language. Back when we started, we connected with a few precision-engineering companies, keen to tell the story of high tolerance levels and material performance.

Nick and Steve run a wonderful precision-machine company in Hertford. As soon as I met them, I knew they were the people we wanted to work with. They worked with me on all of my leftfield requests and each experiment was as interesting to them as it was to me. As a small business we are an abstract client to them and one that could be seen as an inconvenience. Nevertheless, they have always made us feel valued and welcomed our work, delighted to show us their expertise and capabilities.

Beyond our jewellery, we share values for ‘good business’. Nick is a leader in creating a self-sustaining environment for his engineering. He champions a responsible workplace and is always finding working methods to minimise the impact on our planet. ISO14001 certified for the environment management system within the company they are very concious of areas including renewables, packaging, emissions and materials. Over the course of working together they have moved factories to a purpose-built space using the energy created through the work they do to fuel the factory. Paired with this he values mindful workspace and they have built a team of loyal engineers, from apprentices through to the leaders. I look to Nick and Steve as a form of production mentors. They live and breathe their business (in a healthy way) and I learn a lot from them. Their ways of working really are best-in-class, as are their materials and their production processes.

Additional reading: click here

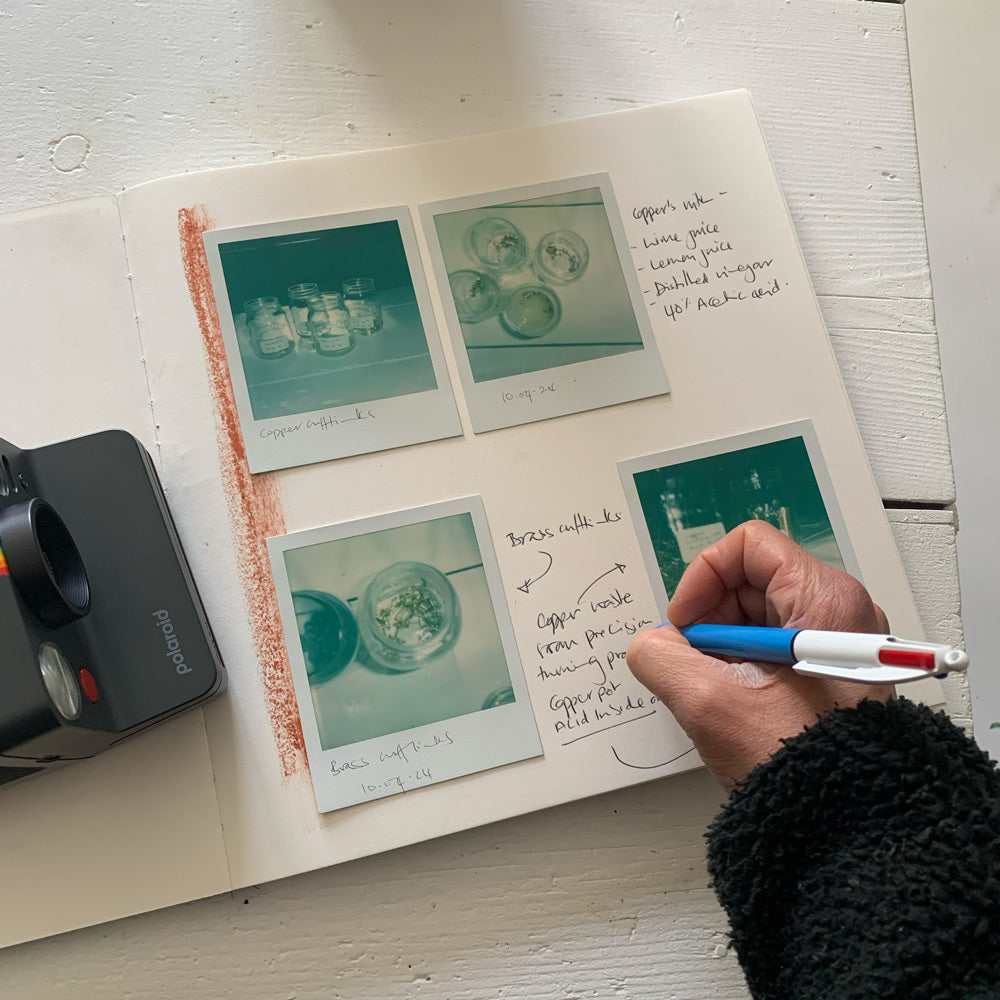

Patina

We have always admired the way materials in our world weather over time - particularly metals. This weathering tells a story, and we loved the idea of observing this in our jewellery. Patination is a natural reaction on metals - think church roofs and longstanding sculptures. This sparked an idea of taking the patina process from the macro scale to the micro. Using our aerospace grade base metals like brass and copper, we started to explore the art of patination and in 2016 we went searching for an expert in this field.

We were keen to find a specialist and one who may be up for transferring the art-of-patina onto jewellery. Derek was introduced to us by a bronze caster we had worked with, and in our first meeting I knew we would work together. We both had the same ‘kid-in-a-sweet-shop’ excitement when we talked through any ideas. He was totally up for exploring new ways of displaying his craft, and we shared a joy of mixing art with science. To me, the Patina process is exactly this! Derek’s expertise in patina makes me think of an impactful chemistry teacher. His honed skill and understanding of his craft is really amazing and his passion for it is contagious. He has a celebrated reputation amongst London’s artists and designers as the go-to for finishing their pieces with the most beautiful patinas.

A patina is an oxidisation upon the surface of a metal. By fast tracking atmospheric conditions, you can manipulate a patina to develop on the metal. Derek creates recipes to do this. Using things like silver nitrate, copper sulphate or titanium oxide, he layers and heats each piece he works with, to create an immediate reaction. The result of this is a deeply coloured piece, with a form of lustre or depth, that only this kind of work can create.

I think what I like so much about the patina process is that it is all applied and worked by hand. The finish you get is totally unique to each piece. It is also integral to the material it is made with. The only way you could possibly get the patina finish on the piece of jewellery, is for the material it is made with to react. I find that really mesmerising and beautiful.

Derek and I continued to work together on studio projects and on jewellery. I feel very grateful to know him and we have a deep respect for each other’s work. Each time I pop in and see Derek in Deptford I am also reminded of creative spaces in London. He is fortunate to still be in an arch under the Deptford railway lines, but many others have been forced out due to rising rents and property moguls. How long he will remain here I don’t know. But our patina jewellery is doing everything in its power to keep him there.

Additional reading: Patina Cufflinks and The Artist & the Artisan

Water Casting

This is a process that is close to my heart for a few reasons. Firstly, we developed it after the global mayhem of the pandemic. The inspiration behind it was about breaking something down and building it into something more beautiful. Secondly, we work with our favourite London casting house, Just Castings. A family run business (and Royal Warrant holder) housed in London’s jewellery heart, Hatton Garden, and Northwest London. We have worked with George, Leo & Theo since our third collection and they feel like our precious metal Jedis! Thirdly we love to look at an age-old, traditional jewellery- making technique, and experiment with it!

George, the production director, has always opened his door to the idea of experimentation and material exploration. The first phase of any project we work on with him is an idea and a conversation. I talked to him about the idea of celebrating imperfection, and we walked through the casting house analysing the process, over and over again, to see where we could adapt a step in the process to create something unusual, responsible, and beautifully imperfect. It was the stage of breaking down the used silver, to go back into the production process, where we struck gold (or rather fine silver!). Here we managed to use their current methods of smelting silver into beads by dropping it into cold water. We manipulate the molten silver flow, its drop height and width, and create organic shapes that appear shell-like or even pearl-like. This process allows us to use the obsolete silver from another casting. This silver would usually be going through this process (albeit it in a more uniform, bead making manner) to return it to a cast-able structure. Instead, we are able to translate it, using a zero-waste process, into beautifully imperfect charms of fine silver.

Every batch of charms that we make are used for our Bardo and Maya Jewellery. We work onsite to create these with George, & one of his team, Jim, in the casting workshops. We work together ensuring the flow, gauge and size is spot on for the batch we need to create, and then collect the charms and head back to the AMT studio to build the jewellery there.

Our Water Cast collections are limited by the number of wax trees that are needed to melt down after a production run, so these pieces are always made in small batches and limited runs. Some of my favourite days are spent in the Just Castings workshops, stimulating the senses with the heat of molten precious metal, the smell of sprue wax, and the sound of hot fine silver plunging into cold fresh water… It is totally dreamy!

Additional reading: Click here

Forging

Our Forging team are based in Farnham. London Bronze Casting (in Farnham not London!) are a team of artists and artisans that we have worked with on various Studio AMT projects creating awards and bespoke gifts. As our relationship has evolved Vincent, one of the founders, shared his journey of craftsmanship. His main passion and craft is the ancient craft of Forging, but this was side-lined by the successful casting business they have built. That was until last year! I expressed an interest in learning more about the art of the Blacksmith a few years ago, and he promised to connect when he had set up the forging workshop in his space that he had always be meaning to create. Unlike me to let things lie, I mentioned Forging to Vincent at every opportunity possible, and he kindly informed me as soon as it was set up and ready for action. We began experimenting in 2019. Using his years of expertise, we explored both hot and cold forging.

Forging is at the heart and soul of Vincent’s passion for metalwork. He thinks and works metal like it is plasticine. He uses metal as a language and as a form of expression. The workshops they create in are hot and mesmerising, and loud yet amazingly tranquil. I think the most absorbing element of it is that the environment is, end-to-end, full of creatives honing their skills. Every step of their production process is done by a trained artist, with graft and grace. Vincent is a total grafter but has a laid-back style to his teaching which creates an aura of respect and a ‘master-of’ force. It is hard to explain in words. It is so graceful to watch him work, yet the work he does is heavy lifting, intense, hard, and very very hot!

Our Forge collection celebrates the skills and art of the Blacksmith. Informed by the primal techniques of forging that date back to 1500 BC the jewellery explores the beauty of imperfection and the idea that no two of us are the same. Vincent and I worked on techniques to elevate this. The precision turned charms are hot or cold forged using mandrils, stampers, hammers, and wire brushes before they are hand polished and made into jewellery with contrasting chains.

Additional reading: The Ancient Art of the Blacksmith & An Expert Forger

Silversmith

This is possibly our most traditionalist technique! The Silversmith is ‘The Jeweller’ as such. When we launched Alice Made This, I never expected to work with a Silversmith. I assumed we would avoid the quintessential techniques in search of more lateral approaches. I am however extremely proud to have a Silversmith in our Craftsmanship legion - especially Dave! I was introduced to Dave through Lou, his wife, who we knew from a partnership on an earlier design project. Dave has an Aladdin’s Cave type workshop in the heart of Birmingham’s Jewellery Quarter.

Dating back more than 250 years, Birmingham’s Jewellery Quarter is Europe’s largest concentration of jewellery businesses and produces 40% of all the jewellery made in Britain. Historically it is the home of many industrial feats, which made it an appropriate location for Alice Made This to explore in more detail. Our minimal and graphic solid silver and gold jewellery, including our wedding rings, are made in Birmingham. Our materials are from Cookson Gold, also based in the Jewellery Quarter, and this jewellery is of course verified and stamped at the Birmingham Assay Office.

An amble from these larger businesses is Dave’s workshop. In this space he simply makes. By simple I mean in a carefree, dedicated, and matter-of-fact way, Dave makes the most beautiful jewellery. What was most telling for me was that Dave was (and still is) called upon by the surrounding jewellery businesses consistently, to support and advise them on their work, and to create for them. Be it a bespoke piece for a local jeweller, a grill teeth design for his neighbouring artist, or to finish a CBE, MBE & OBE for a local manufacturer, Dave has some wonderful stories to tell over a Brummie beer, of projects in all shapes and sizes.

We started working with Dave on our Brutalist collection of rings and bracelets. We needed a craftsman who was willing to try anything, applying expertise, but understanding (or accepting at least) our weird and wonderful requests to explore shapes and finishes. Dave understands our desire for best-in-class. He understands our aspiration for the paired back aesthetic and the celebration of the materials and the process. He enjoys the experiments, and he cares. We spend days in his Aladdin’s cave playing with silver and gold, trialling and re-trialling. I always leave his space inspired and excited by the jewellery we create. Through the journey that is Alice Made This, my trips to and from Dave’s workshop have been cathartic. He offers advice on so much more than jewellery! He reminds me that kindness is golden, and that a slow and steady pace, doing what you love, is so valid in today’s world. He makes me appreciate that over a lifetime of dedication to your role, you continue to build your skillset and develop your craft. He is a gem!

Additional reading: Click here

Hand Engraving

Sam James Ltd are known as Master Engravers. I do not use this term lightly. In the heart of Farringdon, London, Sam James Ltd offer the most prolific engraving service I have come across.

Sam (female) and James (male) began as a company in 2011 to offer outstanding quality and service across all facets of engraving. They set up the business together after recognising each other’s talent. Sam came from a family of gun engravers and trained in this environment and James grew up in the world of antiques. These two experiences are a wonderful combination to their differing approach to engraving. Now a team of five engravers they are two of the humblest individuals I know. They have cleaned up winning so many engraving awards, and they dedicate themselves to passing on their expertise with an apprenticeship programme. Their exceptional team is made up of previous apprentices which is a testament to them and their work. They spend their days with their magnifiers on, scribing metal as if they were sketching intricately on paper. You know when someone has mastered their craft when they make something so complex look effortless.

Sam and James engrave so much wonderful work that most of it you would recognise, or know of it, even if you have not seen it in your surroundings. Plaques across London, elite sporting trophies with cups from polo to golf and of course football (including the FA Cup), engravings throughout the House of Parliament, and even Her Majesty the Queen’s Platinum Jubilee walking stick.

We had worked with Sam James on a Studio AMT project for McLaren F1. During this we became friends and, curious as I am, I asked James all about the heritage behind engraving. It was these conversations that evolved into a collection of hand engraved jewellery. The hand versus the machine was the point of interest. Engraving has a finesse and scribe that loses its character when processed on a machine. Working with James, we wanted to highlight their story and the art of Heraldry which has so much meaning behind the pattern work it uses, both technically and creatively.

Additional reading: Click here

Ocean Diamonds

We have always wanted to use diamonds, but have been nervous of provenance and process, the transparency of which we value highly. I was introduced to Ocean Diamonds in 2019 and it gave me confidence to introduce diamonds into our collection. Ocean Diamonds is a small business based in Falmouth, Cornwall. Robert, their founder, has a career history in marine engineering, through which he had the fortune of meeting fishermen in Namibia who dived for diamonds in their down time when the sea was calm. He became friends which these locals through his engineering work and when this trade ceased, he went on to realise his dream of working with them. Fast forward to today and Robert has set up Ocean Diamonds, a leading specialist in marine diamonds, working with skilled divers and expert artisans to consciously source and carefully certify one of nature’s most precious gifts – the diamond.

These diamonds spend millennia travelling via geotechnical movement from kimberlite pipes in the earth’s crust, down mountains, along rivers, through currents and into the shallows of the ocean waiting to be discovered and hand-picked by these local divers. They are a feat of nature and epitomise resilience in their journey to the sea.

Too good to be true, I spent time with the Ocean Diamond team in Cornwall and it is everything I wanted it to be, and so much more. There is a profound love of nature and the ocean. One that you only get by living and breathing in this environment. They have a purpose driven approach in everything they do and have built this into their business from the ground up. It is such a pleasure to work with a team like this. The relationships, transparency and commitment to responsibility is amazing and I feel very grateful to have found a business like this to source our diamonds for us.

Like most of our processes, the story of this company and the diamonds that they source became the entire body of the collection. It was the inspiration, the information, and the content of the jewellery and these are the sole stones we choose to use in our jewellery. A passion for the sea, a respect for the natural world, and a community that is driven by the science of nature is at the heart of this collection.

Additional reading: Click here

Barrelling

This is a process we use to create our signature matte finish. We developed this through a project exploring the British Coastline. Inspired by geo-technical movement we explored wave patterns, lunar cycles, erosion, and seas defences, both natural and manmade. One of the many experiments we did was to borrow 50kg of genuine British beach stones and barrelled our jewellery in this shingle. We started with our precision turned pieces. Nick and Steve, our Aerospace engineers in Hertford, gave us access to their large tumbler for a few days. Not many factories would let us do this kind of thing! We played with barrelling speeds, different size and shape of stones using our various types of metal. The outcome was to create a finish that is unique and exclusive to Alice Made This. We use a ceramic stone called the Tri-Ninja stone. This stone replicates the size, weight, and method of stonewashing with British beach stones. We have recreated a wave cycle and the idea that your jewellery has been washed up upon the shoreline after an adventurous journey! Don’t worry, we also returned the beach pebbles back to their natural home.

The Alice Made This matte barrelled finish is a contemporary bright finish that has a natural fleck to it. I like to think of it as a fresh twist on an antiquing process. We now do our matte barrelled finish across the collection. We do this is three ways and in size order! Our Aerospace engineers, Nick, Steve and their team have the large barrelling tumbler. Dave our Silversmith has a medium sized tumbler in his workshop, and we have a small desktop tumbler here in the studio. By adapting the quantity of ceramic stones, we use, we can use all three of these barrels to create our signature finish. Each of these locations allows us to minimise the stages of the process and keep things as local to their main production technique, as possible.

Additional reading: Click here

Blasting

Blasting is a finish that I came across when working in the industrial design industry. I like the way it eats into a metal surface to give an undulated sheen. We searched locally for a service of this kind to see if we could find this craft on our doorstep. We did! Based in Penge, South East London, we found George who owned a blasting company restoring vintage motorbikes and cars engines. He specialised in blasting, offering both coarse and fine, wet and dry options. Over the course of a year, we worked with George to experiment with the different finishes we could create.

George grew up in South East London and found traditional education a challenge. His teachers were perpetually frustrated by his un-tapped potential. George finished school at 16 itching to start making money and began working with a local craftsman. This craftsman happened to be a blaster who reconditioned antiques and vintage machine engines. George had a lifelong interest in mechanics, and was quickly absorbed by all this machinery, and so he began to learn the art of blasting. By the time George was 24 years old, the craftsman was ready to retire and offered George his business, confident that he had mastered his craft and would build the business well. It is rare to see George’s level of craftsmanship and finesse so young, but 8 years of intense training and a raw passion for motorbikes ignited the entrepreneur.

We continue to work with George after meeting him in 2016. He now splits his time between supporting young people, who also struggle with school, by equipping them with skills like mechanics, and blasting. I love this cycle of taking ownership of who you are and what you believe in.

George handworks all of our blasted pieces. We use a coarse dry blasting. Iron filings are blasted at high pressure against our jewellery to eat into the surface of the metal. This gives a brick type texture that we soften with a wet glass bead blasting. The end result is a raw and refined finish with a satin sheen. It is a finish that works for people who like something brutal, but also for those who like something uniquely refined.

Additional reading: Click here

Stone Carving

I was introduced to Phil through another stone carver, craftsman, and friend, Simon Smith. I met in Phil Surey in Deptford at his beautiful workshop. We talked through the process, history, craft, and Immediately I was keen to celebrate his expertise. The relationship and understanding evolved, and stone carving was the starting point for our Alphabet collection.

His art of letter carving, is considered a somewhat anonymous art. A quiet art, carved with artistic liberation, geometric accuracy, and technical excellence, yet one that remains largely anonymous, as no one puts their name against this wonderful craftsmanship! It was this anonymity that affected me. Shining a light on an unsung heroe of craftsmanship, studying a new process, and further exploring the geological wonder of stone was a project that I had to engage with! And so, a project began.

Graduating in 1996 from the City & Guilds of London Art School, Phil had spells assisting two of the great letter carvers, Richard Kindersley and Ralph Beyer, before establishing his own workshop in South East London, where we had the pleasure of working with him. His humble demeanour veils his amazing client list that includes The National Trust, Tate Britain, Southwark Cathedral, Westminster Abbey and Winchester Cathedral amongst many more personal commissions and projects. Here Phil and I explored the history of lettering and the people that shaped stone carving as an art, through the Alphabet collection. We chose stones to carve, for their locality and purpose. We looked at lettering that appealed to us both through its font heritage and industry affiliations. Phil designed the lettering for the Alphabet Collection by brush & pencil before transferring to stone and carving the ‘tools’ through which I can then create each piece of Alphabet jewellery.

Each time I create a piece from these stone tools I feel like I am deeply celebrating all the anonymous craftspeople that are visible through the architecture around us.

Additional reading: Click here

--------------------------------------------------